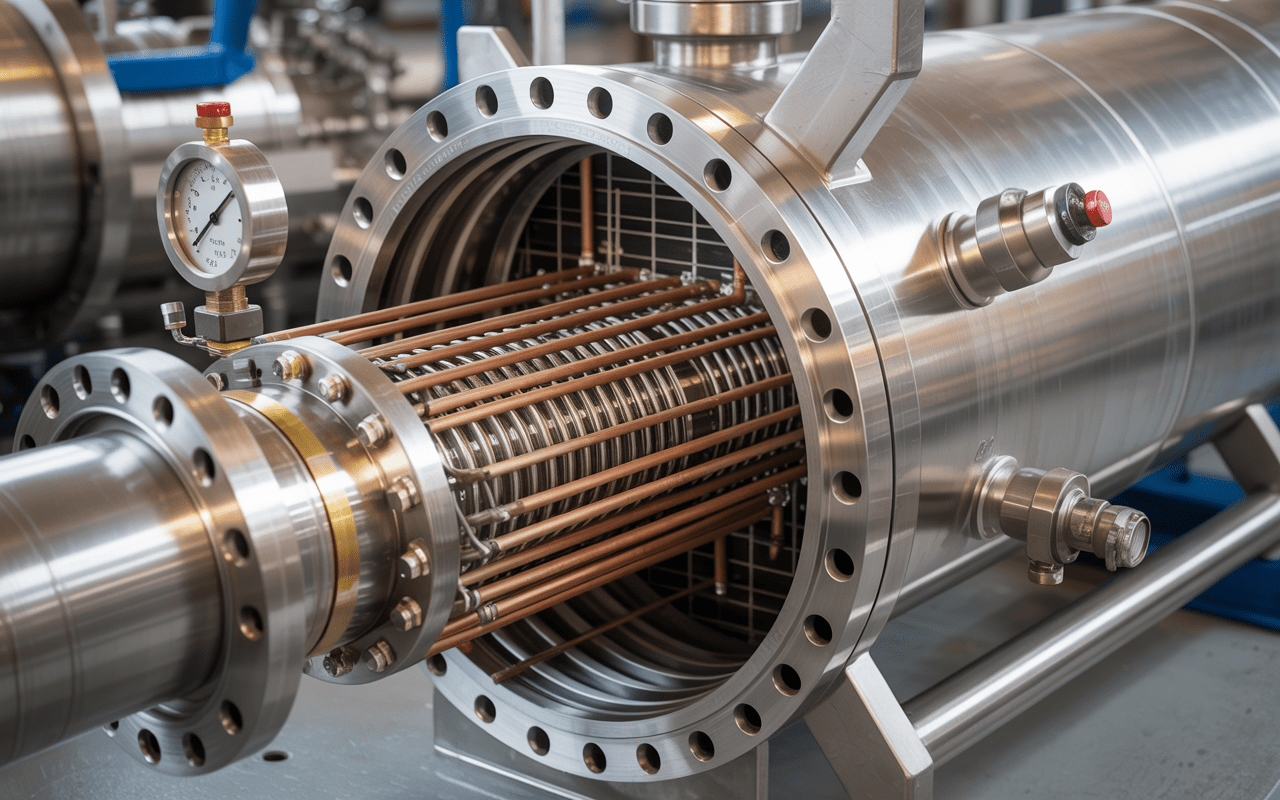

Our Core Offering: Shell and Tube Heat Exchangers

Shell and Tube Heat Exchangers are the most reliable choice for heavy-duty, high-pressure, and high-temperature industrial heat transfer. At EPV Tanks, we specialize in custom designing every unit to optimize thermal efficiency and minimize downtime in your critical operations.

Custom Configurations and Thermal Design

- TEMA Standards: Full custom fabrication to TEMA (Tubular Exchanger Manufacturers Association) configurations.

- Advanced Thermal Design: Precision engineering for Counter-Flow and Cross-Flow arrangements to maximize heat recovery.

- Capacity: Scaled up to 82 ft long and 14 ft wide (max diameter).

Shell and Tube Exchanger: The most reliable industrial design.

Why Choose EPV for Your Industrial Heat Exchanger?

ASME Code & Compliance

Every unit meets the strict requirements of the ASME Boiler and Pressure Vessel Code (BPVC). We provide full calculation reports and ensure the highest standards for safety and regulatory compliance.

Engineered Materials

We fabricate with materials optimized for your process fluids: Carbon Steel, Stainless Steel, and specialized corrosive-resistant Alloys (Inconel, Hastelloy, etc.) for high-temp/high-pressure duty.

Complete Lifecycle Service

From initial design and thermal modeling to expert manufacturing and ongoing service support, EPV is your single source for custom thermal solutions.

Key Industries and Applications

Chemical & Petrochemical

Cooling exothermic reactors, solvent condensing, and heating process streams in harsh environments.

Oil & Gas

Intercoolers, aftercoolers, reboilers, and condensers for refinery and processing operations.

OEM Integration

Custom heat exchangers designed for integration into larger industrial systems, skids, and equipment packages.

Frequently Asked Questions About Heat Exchangers

Find quick answers to the most common questions about our ASME-certified Shell and Tube Heat Exchangers manufactured in the USA.